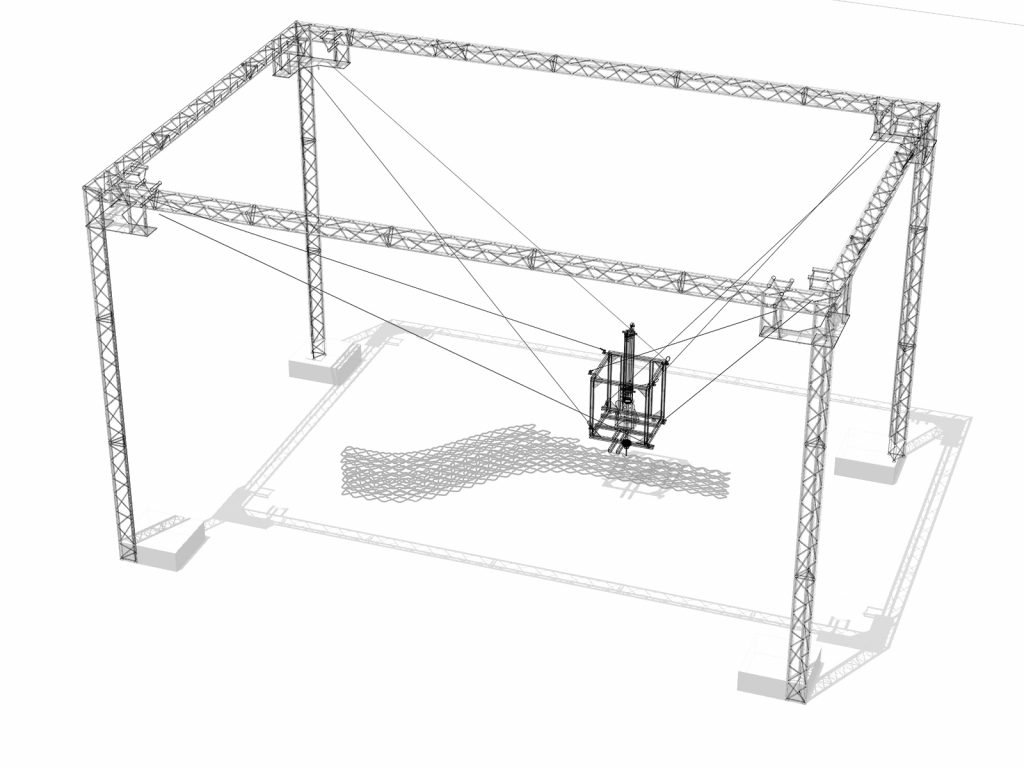

The 3D Printing System presented in On Site Robotics is introduced to 3D print large-scale construction parts, and even small-scale buildings, made from natural materials. This system includes the cable robot Cogiro with an integrated CNC control, which is able to automate the movement of the 3D extruder with precision.

Thanks to the use of cables operated by servo-controlled winches with easy assembly, maintenance and reconfiguration, the printing can happen in a very wide range of workspaces, and even directly on the construction site.

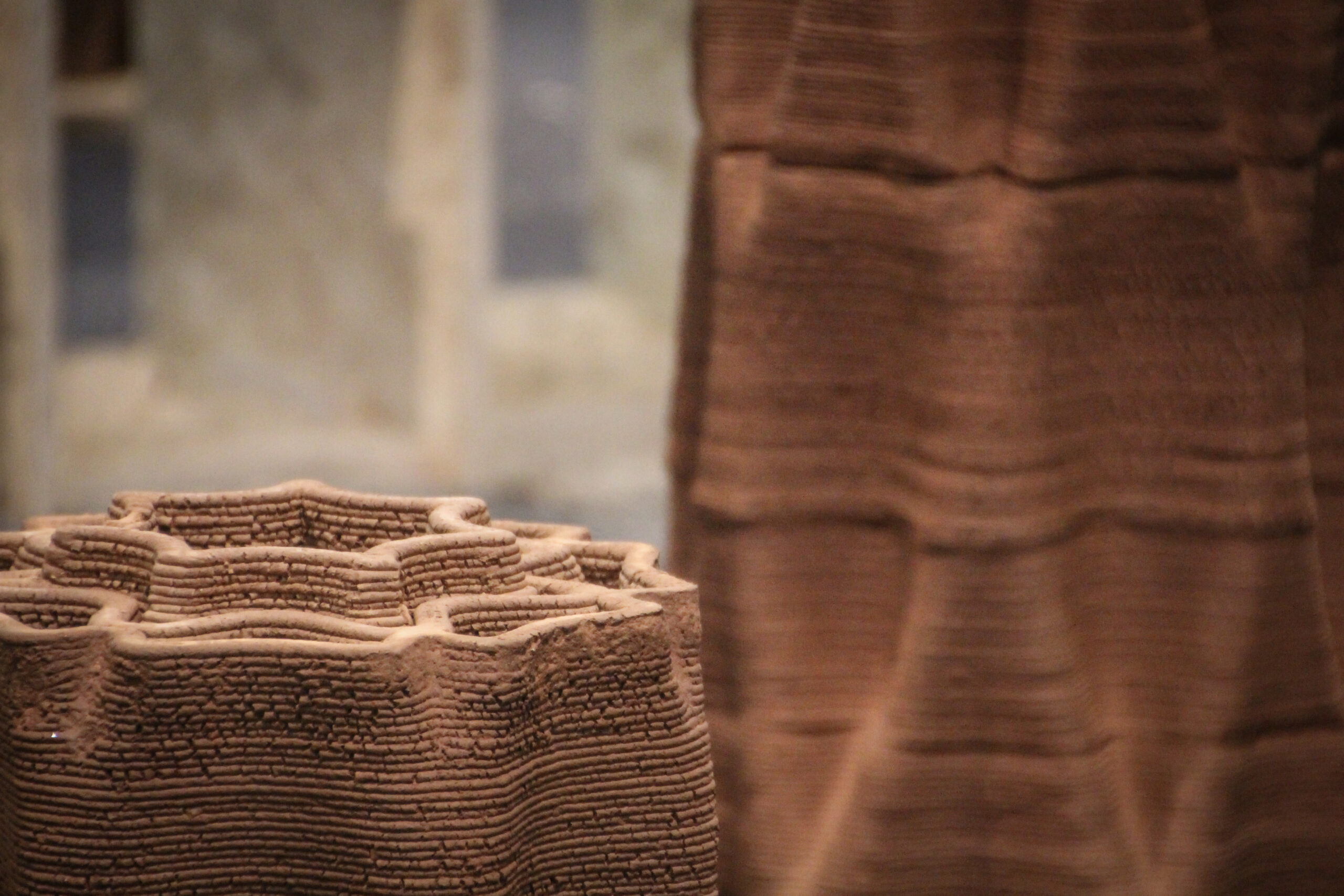

The system also integrates an extruder and a natural, biodegradable, recyclable and local clay-based extrusion material, based on the Pylos project. In addition, a custom script integrated in the CAD software allows to easily translate the complex forms of 3D design in the robotic trajectories.

In addition, the On Site Robotics scenario integrates the use of drones programmed to fly autonomously. Its objective is to participate in the workflow, monitoring the development through multispectral cameras, which, thanks to computational processes, offer thermal information of the drying state of the structure.

This information is necessary to control the printing process, avoiding the superimposition of new layers of material on a still fresh and unstable base.

The Construction sector, which has traditionally been slow in integrating technology, is now opening up to digital manufacturing, 3D printing, and robotics. The possibility of printing anything that has been previously modelled in our computer lays the groundwork for a true change in the conception architectural production, and in the possibilities of personalising the final product.

The system developed in On-Site Robotics aims to revolutionize the construction sector, reducing production costs and offering the inviting possibility to customize the final product, that can be built on site or close to the site of construction.

So far an extruder for clay material has been developed, and in the near future, an extruder for the cementitious material will also be available. Thanks to the system presented, the automatic 3D printing of large architectural elements and small buildings is close to being a reality.