Ongoing

Living Prototypes

Digital Fabrication Processes and Prototypes for Resource-Conscious Living Spaces

Living Prototypes responds to the concluding aims of ANCB’s 2017 discussion series Craftsmanship in the Digital Age. Architecture, Values and Digital Fabrication: It supports the transfer of advanced research from the laboratory to architecture practice, demonstrates how digital technologies enable the building industry to switch to resource-efficient building materials and construction, stimulates a digital building culture, and prompts further exploratory applications of digital fabrication in the sustainable construction, use and maintenance of buildings.

RESEARCH PROJECTS

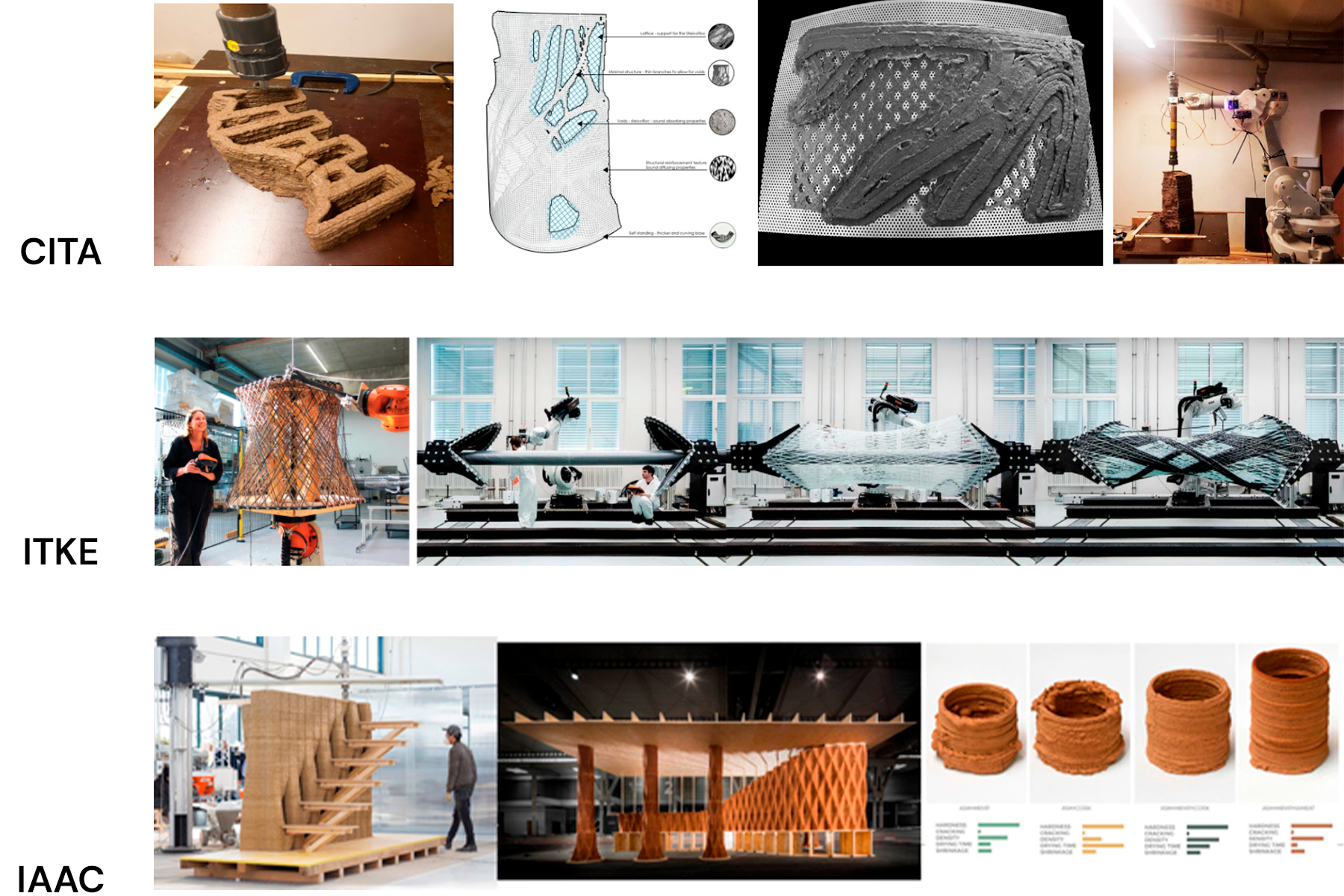

BIO-BASED LIFECYCLE MATERIALS – Cellulose Enclosures

CITA – Centre for Information Technology and Architecture, Copenhagen and COBOD International A/S, Copenhagen

In contrast to the petroleum-based plastics used for 3D-printing, cellulose-based bioplastics are renewable, inexpensive, biodegradable and chemically diverse. Digital data analysis technologies, such as machine learning, make it possible to predict and control the behaviour of these materials during and after the printing process. CITA and COBOD will explore components for interior spaces made possible by this adaptive manufacturing process, and with the perspective of material lifecycles and circularity in building.

NATURAL FIBRE WINDING – Composite Installation in Existing Buildings

ITKE – Institut für Tragkonstruktionen und konstruktives Entwerfen, Universität Stuttgart and FibR GmbH, Kernen

The fabrication technique of robotic fibre winding produces material-efficient architectural components, as no formwork is required and no cut-offs are produced. The amount of fibre used corresponds exactly to what is needed for structural performance. ITKE and FibR investigate winding with flax-based materials, rather than the fossil-based materials used to date. By developing composite prototypes that engage with the existing materials and geometries of the Aedes exhibition space, adaptability in living spaces will be explored.

LOCAL MATERIALS – 3D-Printed Earth-Based Structures

IAAC – Institute for Advanced Architecture of Catalonia, Barcelona and WASP, Massa Lombarda

Earth is a traditional and inexpensive building material, for which extensive technical knowledge exists locally. IAAC and WASP employ 3D-printing and computational design to improve the structural and climate-regulation performance of earth construction, advance its aesthetic capacity and make the construction process more efficient and feasible for infill and other forms of built environment densification. Material local to the Berlin area will be combined with bespoke additives for the robotic fabrication of a prototype for an internal building component.