2013

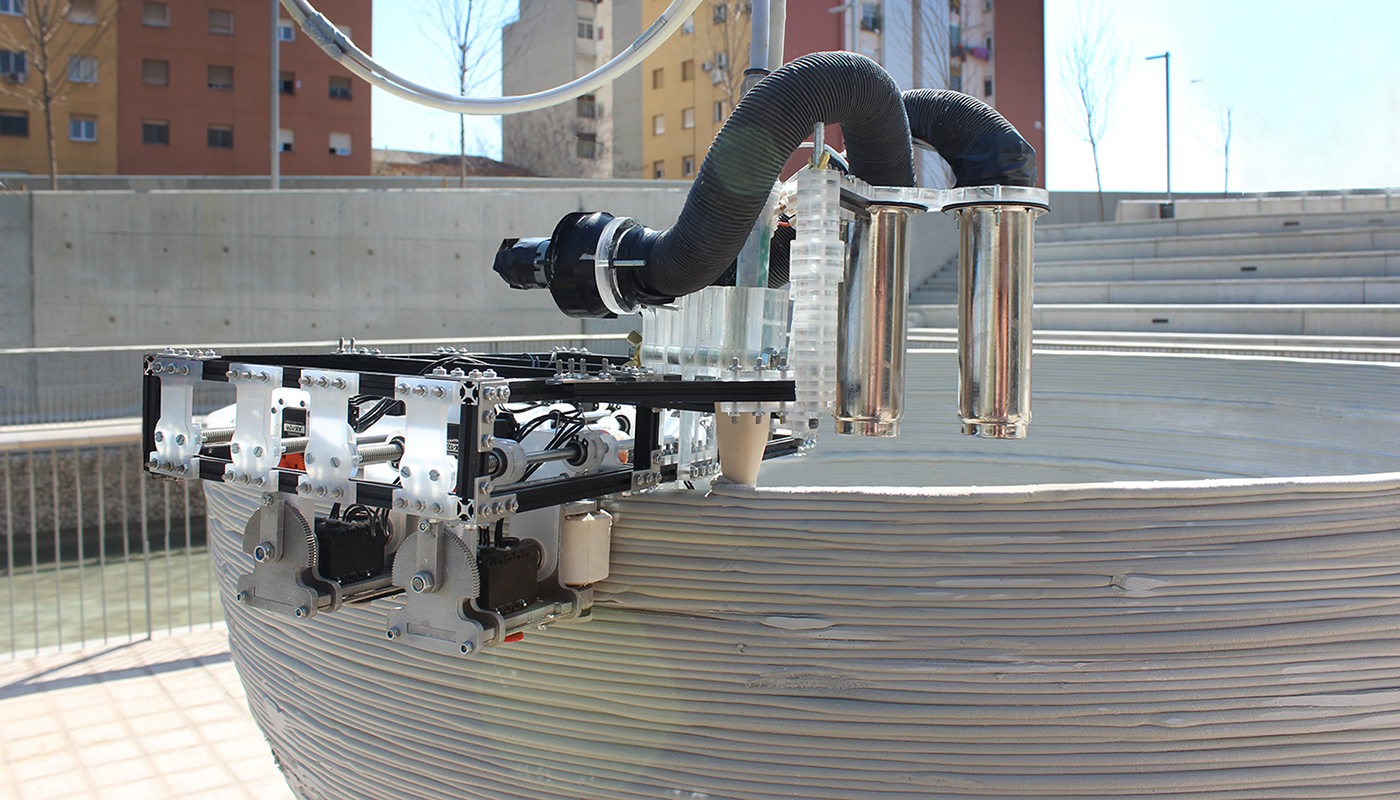

Minibuilders

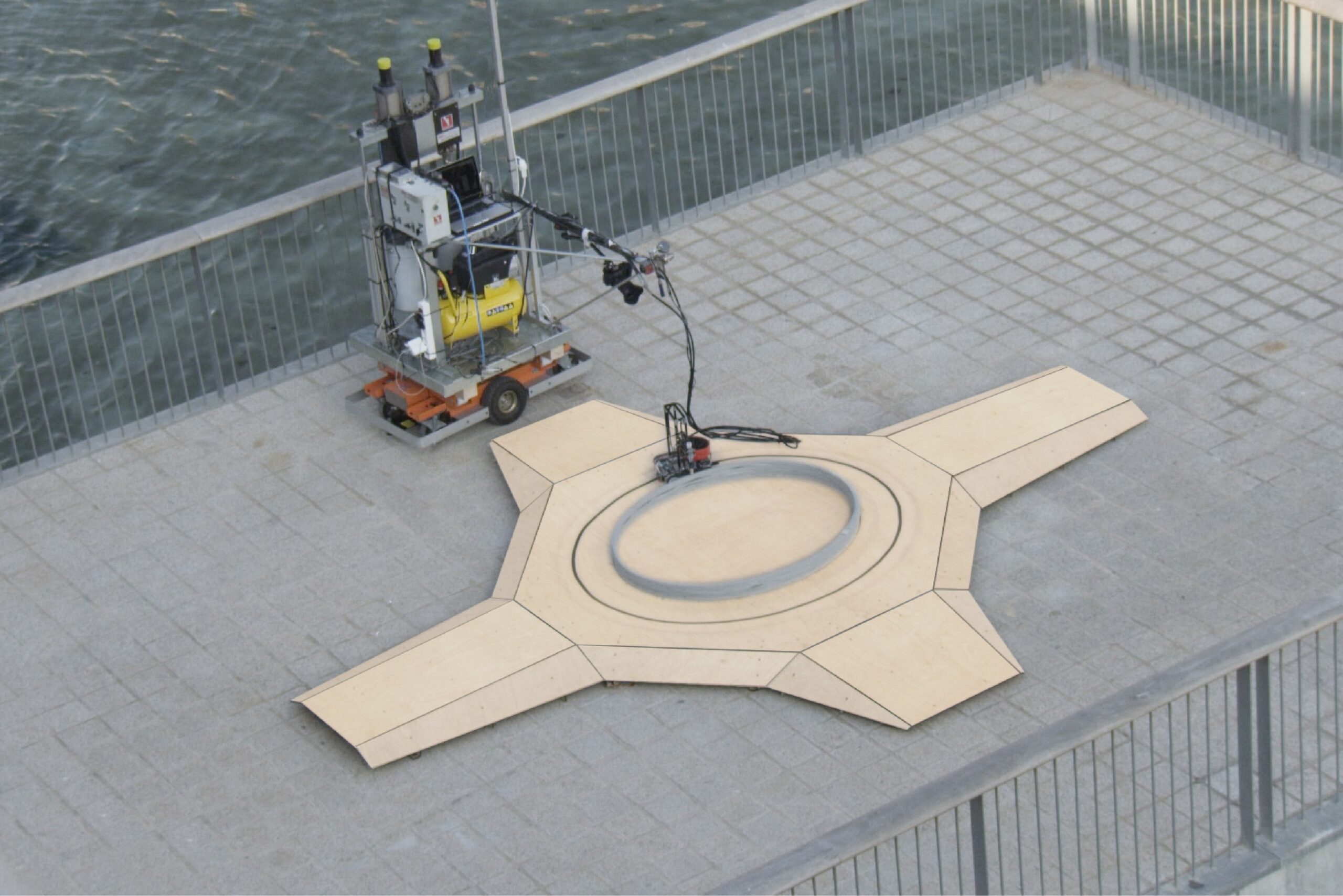

SMALL ROBOTS PRINTING LARGE-SCALE STRUCTURES

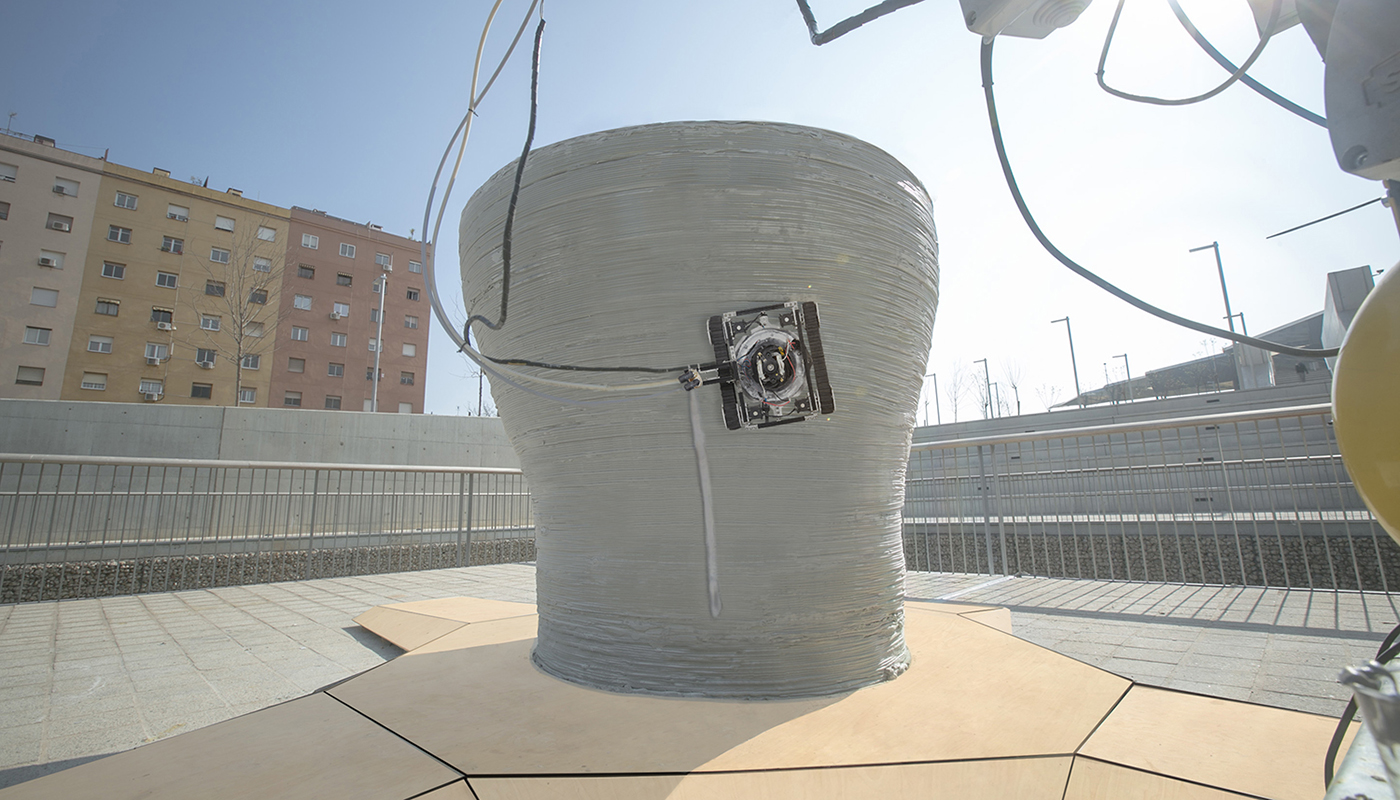

Robotics offer great potential towards innovation within the construction industry. However, in their current implementation applied to the architectural field, in particular, construction robotics, these systems all share a specific limitation: the objects they produce are linked to and constrained proportionally to the size of the machine. This methodology of production and construction is not scalable. In this sense, to create a house, using current construction robotics, the machine needed must have a work envelope as large as the house itself.

Hence, the project here below elaborated aims to address this particular limitation through the creation of a technology that is both scalable and capable of fabricating structures using tools that are independent of the final products shape of size.

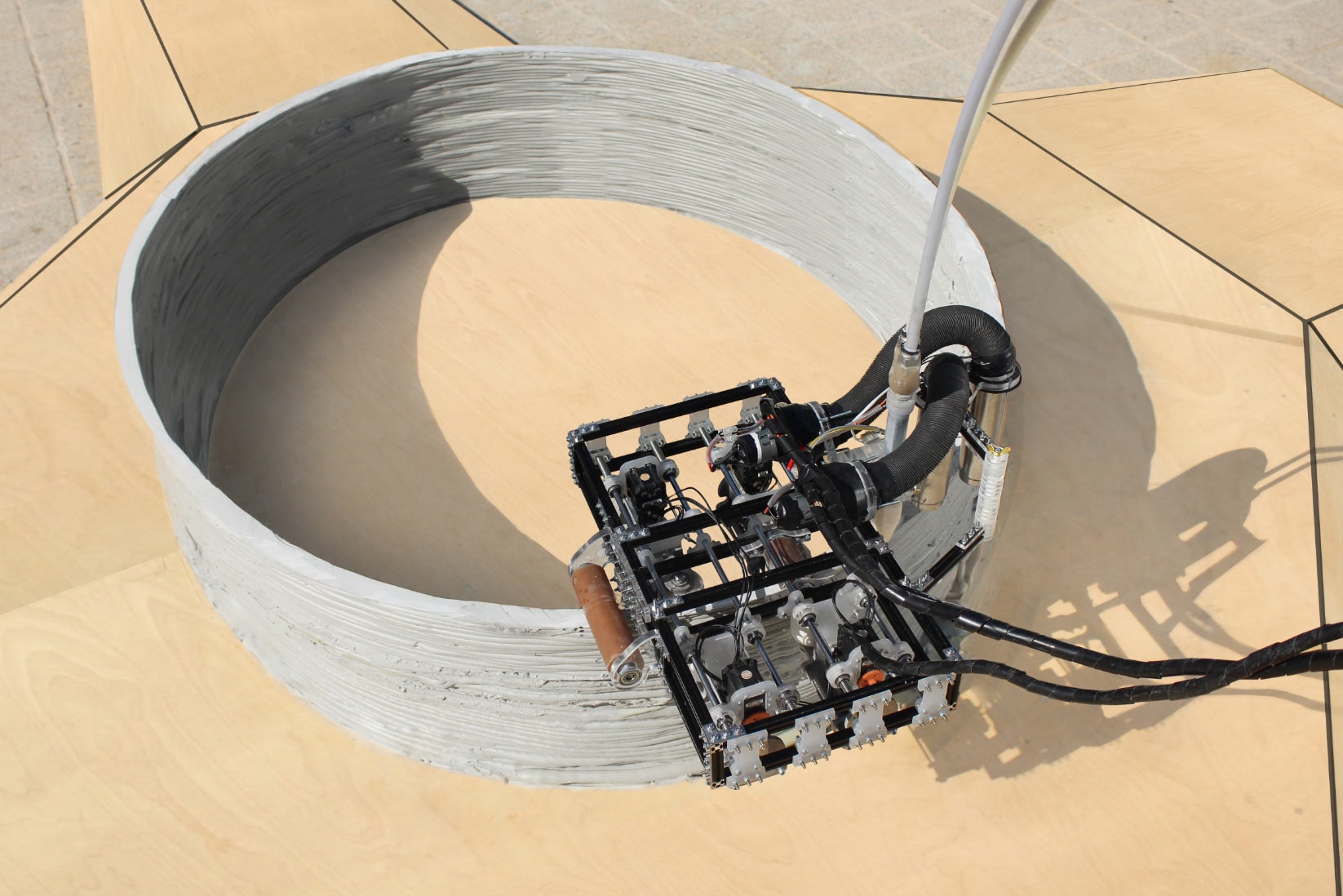

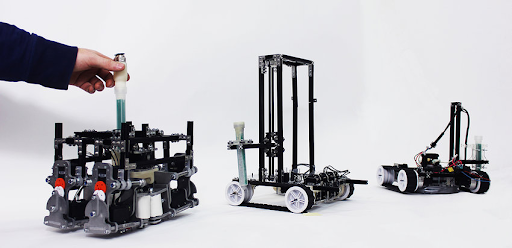

The objective was to develop a family of small-scale construction robots, all mobile and capable of constructing objects far larger than the robot itself. Moreover, each of the robots developed was to perform a diverse task, linked to the different phases of construction, finally working together as a family towards the implementation of a single structural outcome. Hence, instead of the implementation of one large machine, a number of much smaller robots were generated, working independently, but in coordination, towards a single goal.

Specifically, a family of three robots was developed, each robot linked to sensors and a local positioning system. These feed live data into a custom software which allows us to control the robots’ movement and deposition of the material output: fast setting artificial marble.