Barcelona

October, 2020

“Terracotta Biennal” of La Bisbal

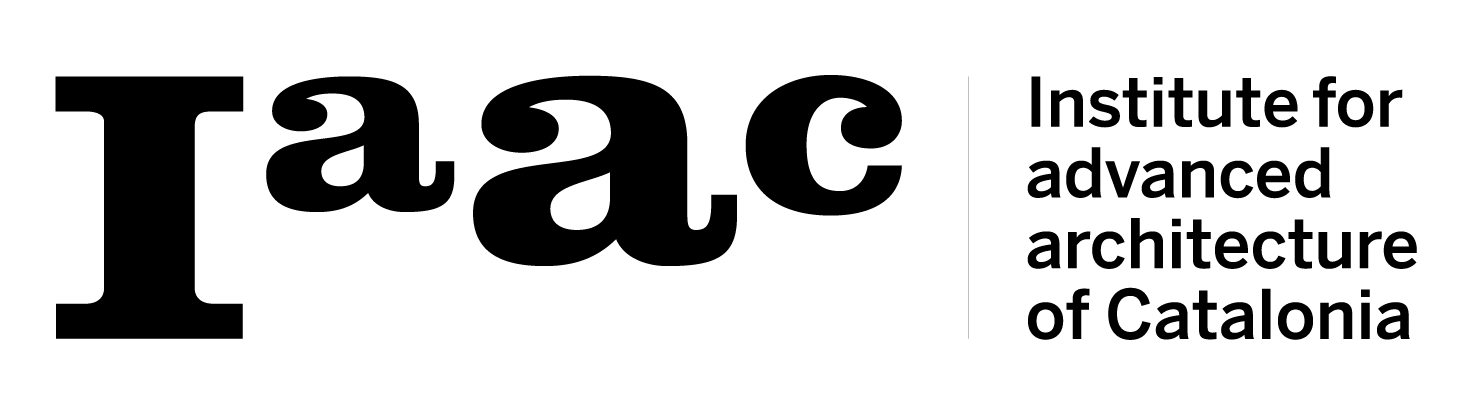

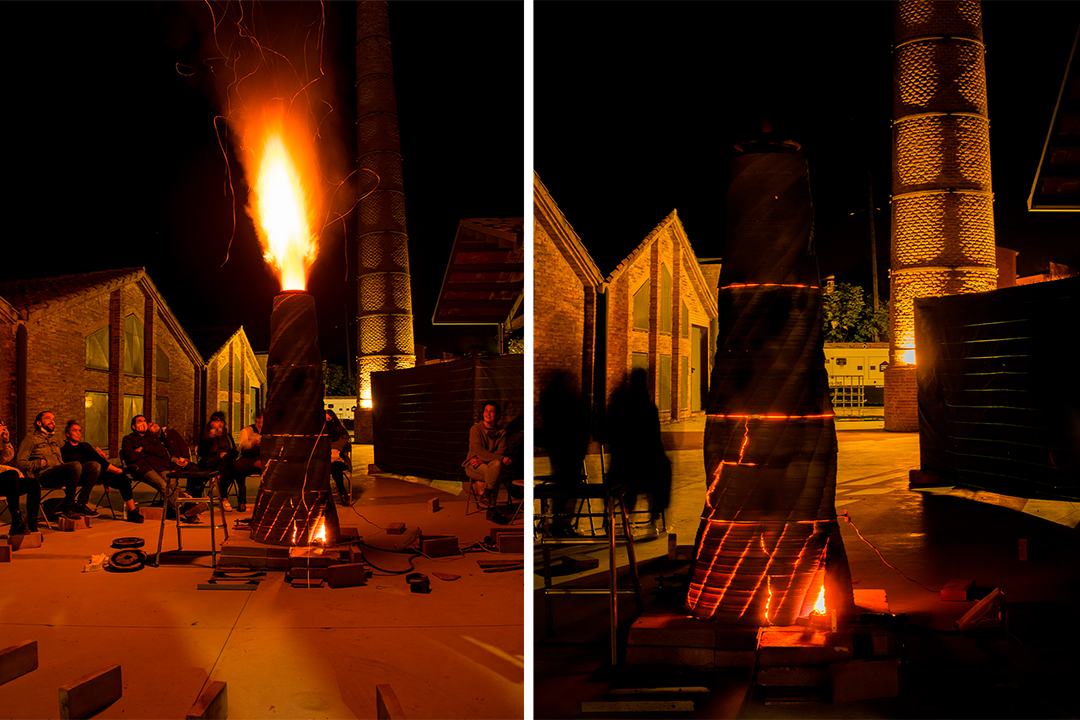

How can we design and construct a building that enables it to be its own kiln? Fenix is a research project of on-site firing of architectural elements that appropriates the capacity of 3D printing to work with cavities: the design of these narrow spaces is used in order to channel fluxes of heat throughout the inside of a wall in order to fire it, converting it into ceramic and strongly enhancing its structural property.

To avoid cracking, the firing temperature inside and outside of any object needs to be equal, hence the most common technique to facilitate this control being to place them in a kiln. This project takes advantage of 3D printing and its possibility to construct cavities that can take on the role of the kiln in order to print a column surrounded by an additional layer that only serves the temporary role of maintaining the heat inside. After the firing at 1200ºC during 15 hours, this temporary layer is removed, revealing the column that had partially vitrified.

For this first large scale experiment in firing earth prints, the typology of the column was used, with the intention to bring this technique to other architectural elements, such as walls, and finally all the way to the scale of buildings. Its key advantage is on-site firing: being able to print an earthen building and fire all, or some of its parts, without having the necessity to use off-site processes such as a kiln.